- Research

- Publication

Published:

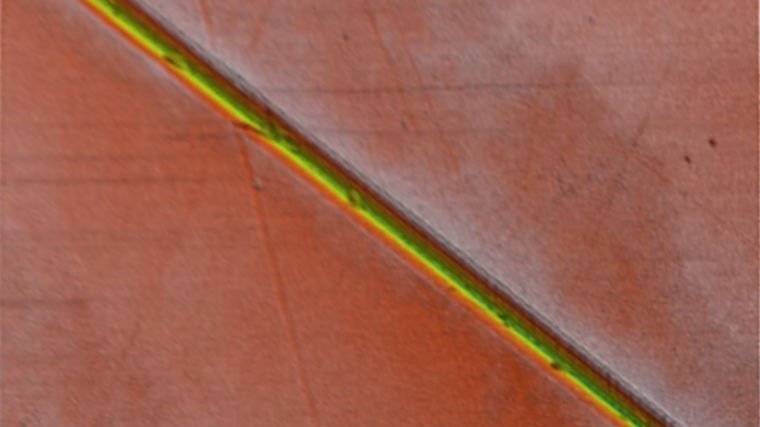

We report on the formation of regular surface ripples accompanying microscratching of vitreous silica using Berkovich diamond tips. The tips were pulled laterally along the surface with varying normal load of up to 30 mN and scan velocity of up to 500μm/s. Post mortem AFM analysis and independent confirmation through laser scanning microscopy reveal the occurrence of regular surface ripples in the wear grooves. The average repetition distance of the ripples is in the sub-μm range and increases linearly with the scan velocity. Their corrugation is on the order of a few nm, increasing with the applied load, and well below the indentation depth (of a few hundred nm). The experimental results are interpreted assuming that the tip moves in a stick-slip fashion, while it is elastically driven along the surface. In this framework the static friction to be overcome in the stick phase corresponds to the lateral hardness of the material, whereas the kinetic friction slowing down the tip results from the plowing motion of the latter.

Publication

Enrico Gnecco, Jana Hennig, Elham Moayedi, Lothar Wondraczek: "Surface rippling of silica glass surfaces scraped by a diamond indenter", Phys. Rev. Materials 2 (2018) 115601, DOI: 10.1103/PhysRevMaterials.2.115601External link