- Research

- Publication

Published:

Fine defect engineering of graphene friction

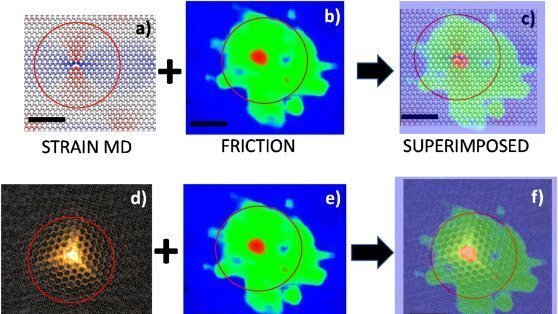

Two-dimensional materials, in particular graphene, exhibit a low friction coefficient and good wear properties. However, the tribological properties of these materials strongly depend on faint differences at the atomic level, and the coexistence of different type of atomic defects in studied samples up to date led to experimental results difficult to reconcile. In our work, we quantified the influence of controlled-induced atomic monovacancies on the frictional behaviour of graphene. Less than 0.1% of atomic vacancies induced a fivefold increase in the effective friction coefficient. We showed that friction force microscopy resolved monoatomic vacancies and provided the real-space distribution of their influence on the tribology of graphene. Two factors contributed to this increment in friction: one was related to enhanced reactivity of dangling bonds localized at the monovacancy (∼1 nm2), that accounted for ∼20% of the increase; and a more extended one (∼25 nm2) arose from the long-range strain distribution around these defects, characteristic of graphene. These results unveil the subtle connection between friction, reactivity, and mechanical properties in two-dimensional materials.

Publication

A. Zambudio, E. Gnecco, J. Colchero, R. Perez, J. Gomez-Herrero, C. Gomez-Navarro: "Fine defect engineering of graphene friction": Carbon, doi.org/10.1016/j.carbon.2021.06.064External link