Published:

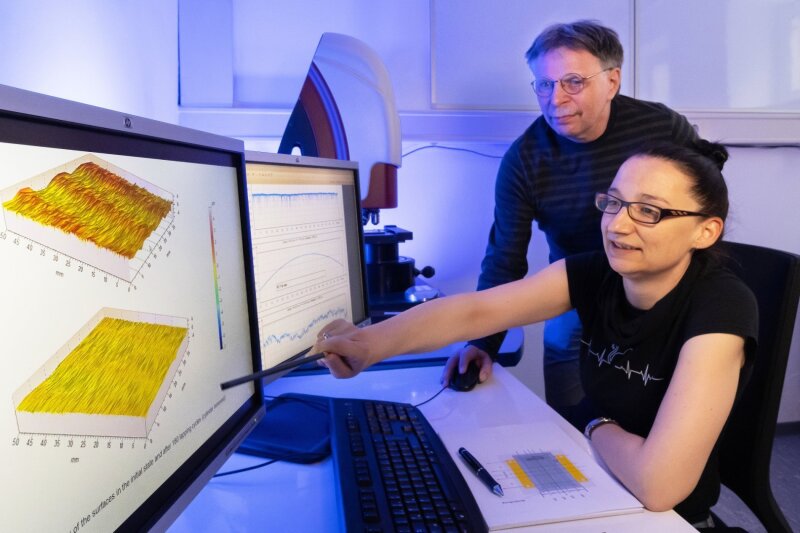

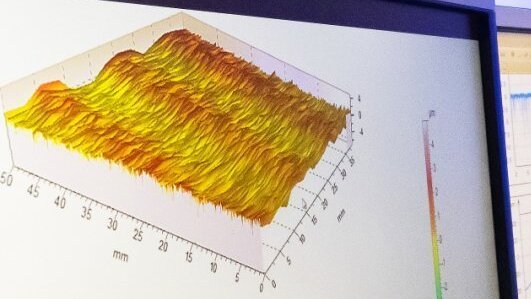

Die Materialwissenschaftler Susanne Sandkuhl und Volker Herold werten eine 3D-Oberflächenmessung aus

Image: Jens Meyer (University of Jena)How can weakly curved cylindrical and toroidal surfaces, i.e. slightly curved surfaces, with radii of curvature of 200 to 20,000 millimeters be precisely machined? This was the challenge facing materials scientists Dr. Volker Herold and Susanne Sandkuhl in the Department of Mechanics of Functional Materials at the Otto Schott Institute for Materials Research at Friedrich Schiller University in Jena. Parts of a precision tool used to assemble an X-ray mirror for a space observatory had to be machined. The mirror to be manufactured is to be launched into space by satellite in 2031 as part of the Athena mission of the European Space Agency (www.the-athena-x-ray-observatory.eu). Dr. Herold from the University of Jena is working closely on the project with partners in the Netherlands and Sachsen-Anhalt...

read more here: https://www.uni-jena.de/210609_TorusflaechenExternal link