- Research

- Publication

Published:

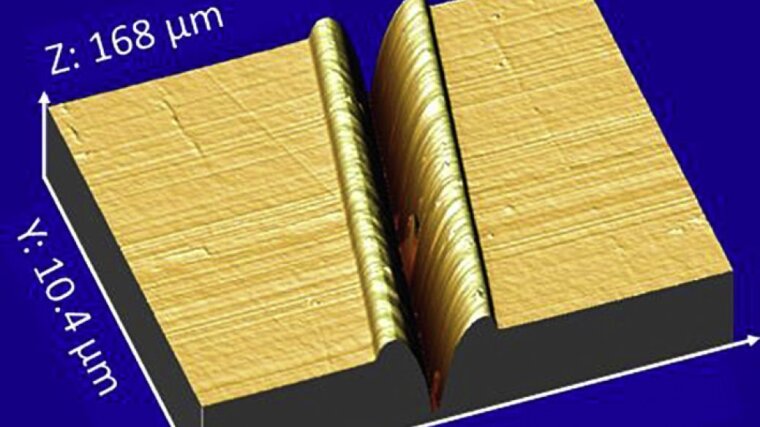

Similar to normal indentation studies, structural compaction and shear flow occur also in the lateral deformation of glass surfaces through scratching. Here, we apply instrumented indentation with tangential displacement in order to study the elastic-plastic regime of scratch-deformation on silica, borosilicate and soda lime silicate glasses. We adopt the protocol of volume recovery analysis by high-temperature annealing to determine variations in geometry and volume of the scratch groove before and after the release of scratch-induced densification. While very similar relative recovery behavior is found for both normal indentation and scratch testing, inherent differences occur in the absolute presence of deformation modes across all three types of glass. In particular, caused by shear deformation at the apex of the employed Berkovich scratch tip, pronounced material pile-up occurs in scratching for normal loads which are about one order of magnitude below reference experiments of normal indentation. This leads to an increase in the effective friction coefficient and a non-trivial correlation between the scratch hardness and the normal hardness of glasses.

Publication

Elham Moayedi, Shigeki Sawamura, Jana Hennig, Enrico Gnecco, Lothar Wondraczek: "Relaxation of scratch-induced surface deformation in silicate glasses: Role of densification and shear flow in lateral indentation experiments", Journal of Non-Crystalline Solids 500 (2018) 382–387, DOI: 10.1016/j.jnoncrysol.2018.08.032External link