- Research

- Publication

Published:

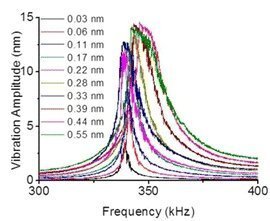

Contact resonance spectra at different ultrasonic excitation amplitudes

Graphic: MfM/ FSUWear on the nanoscale, as evidenced by the formation of periodic ripples on a model polystyrene thin film while a sharp tip is sliding on it with a normal force in the μN range, is shown to be suppressed by the application of ultrasonic vibrations of amplitude Aexc. An accurate calibration of the transducer excitation amplitude is achieved by a home-built setup based on a laser Doppler vibrometer. The corrugation of the typical ripple pattern that is formed in the absence of vibrations is reduced when the excitation frequency matches the contact resonance of the system and Aexc progressively increases. Above a critical value of Aexc, the ripples completely disappear, while the friction levels off at a finite value determined by the normal force and the vibration amplitude. This value can be significantly smaller than the value of the macroscopic friction coefficient. In addition to the control of wear in general, this opens up the possibility of controlled nanolithography with improved accuracy.

Publication

Patricia Pedraz, Reinhold Wannemacher, Enrico Gnecco: "Controlled Suppression of Wear on the Nanoscale by Ultrasonic Vibrations", ACS Nano 9 (2015) 8859, DOI: 10.1021/acsnano.5b02466External link